After the decision is made to begin composting, the next task is deciding what kind of compost pile or structure would be best suited to the area set aside for this purpose. Choose from simple, homemade holding bins to expensive commercially produced units. Your selection should be based on practical criteria such as price, convenience, usability and aesthetics.

MAIN TYPES OF BINS

Stationary bins: These bins sit in one place for the duration, unless you exert time and effort to relocate them. Examples include a bin made of concrete blocks, recycled lumber, or a wooden two or three-bin unit.

Movable composters: Movable bins are nice if you have just one container and want to turn your compost regularly to aerate or re-moisten it. Lift the container off the pile, set it aside, and fork or shovel the organic matter back in. Examples of easy-to-move containers include a homemade wire enclosure, a lightweight plastic model without a bottom, and a manufactured wire bin with collapsible sides.

Open bins: Examples of open bins include homemade square bins made of shipping pallets and manufactured circular enclosures made of lightweight recycled plastic with pre-formed ventilation holes. Although they are easy and inexpensive to build, your material can dry out faster or become too wet, depending on climate.

Closed bins: Closed bins are sealed from the elements. Homemade wooden bins with hinged tops and sheet metal bottoms (with drainage holes) serve as an example. Many manufactured options are available. They discourage pests, but are usually more expensive than open bins. These closed bins can easily become overly moist if too much ‘green’ materials are used so moisture levels should be monitored.

Commercially Produced Bins

Tumblers: A basic tumbler style is shaped like a canister that is rolled over the ground to mix the materials. Other styles include a large drum that rests on its aboveground stand with a hand crank to turn it, and smaller units that are grasped and spun as they rest on slightly concave pads on the ground.

One problem with tumblers is that fresh, moist materials occasionally clump into a compacted, heavy ball so attention needs to be paid to the proportion of ‘green’ to ‘brown’ materials placed inside the bin. How easily the unit can be turned depends upon its style and weight, how much and what type of organic matter it is filled with, and a person’s physical limitations.

Plastic Static Bins: Round or rectangular bottomless bins are typically less expensive than tumblers. Organic materials are deposited in the top and finish compost removed through a bottom door. Turning the materials is often difficult in smaller bins so either use a compost aerator or lift the bin off of the materials, mix them up and put them back into the bin.

Home Made

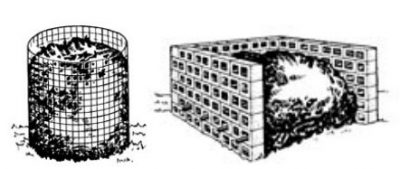

Holding Units: These are simple containers used to store garden waste in an organized way until these materials break down. A holding unit is the easiest and least expensive way to compost. It only requires placing wastes into a pile or bin as they are generated. Non-woody materials, such as grass clippings, crop wastes, garden weeds, and leaves work best in these systems. A holding unit can be a cylinder formed of wire (chicken wire is too weak to hold up to the bulk), or wood scraps. Openings in the sides need to be large enough to permit plenty of air but small enough to contain the materials that are decomposing.

Trash Can Bin: To convert a plastic trash can into a composter, cut off the bottom with a saw. Drill about 24 quarter-inch holes in the sides of the can for good aeration. Bury the bottom of the can from several inches to a foot or more below the soil surface and press the loosened soil around the sides to secure it. Partially burying the composter will make it easier for microorganisms to enter the pile.

Wire Bins: Use an 11-foot length of 2-inch x 4-inch x 36-inch welded, medium-gauge fence wire from your local hardware or building supply store. Tie the ends together to form your hoop. A bin this size holds just over one cubic yard of material. Snow fencing can be used in a similar fashion. Another option is to make a square wire bin composter. Eventually it could be expanded to form a three-bin unit if needed.

Block or Brick or Stone Bin: Lay the blocks, with or without mortar, leaving spaces between each block to permit aeration. Form three sides of a 3-to 4-foot square, roughly 3 to 4 feet high.

Wood Pallet Bin: Discarded wooden pallets from factories or stores can be stood upright to form a bin. Attach the corners with rope, wire, or chain. A fourth pallet can be used as a floor to increase air flow. A used carpet or tarp can be placed over the top of the pile to reduce moisture loss or keep out rain or snow. Make sure pallets are not treated with chemicals or pesticides before using.

Multi-bin systems: More experienced composters and those with large amounts of organic materials might consider two or three bin systems. The different bins are at various stages in the composting process so there is usually a more steadier supply of compost for gardens. Having two or three bins also allows for one section to be used for storing materials, one for active composting, and one for curing or storing finished compost. Each bin should be at least 36 x 36 x 36 inches. Be sure to allow air spaces between the sidewall slats, and make the front walls removable (lift out slats) for easy access. Lift-up lids make adding materials easy and can be put in place during heavy rains to keep the pile from getting too wet.

By Brad Armstrong, UConn Master Composter & Dawn Pettinelli, Associate Extension Educator. Updated 2019.

Questions? Contact:

UConn Soil Nutrient Analysis Laboratory

Department of Plant Science and Landscape Architecture

Phone: 860.486.4274

Email: soiltest@uconn.edu

Website: soiltesting.cahnr.uconn.edu

UConn is an equal opportunity program provider and employer.

©UConn Extension. All rights reserved.